As part of my Summer 2024 internship at JSW Steel USA, I led a project focused on enhancing the mechanical performance of ASTM A516-70 and A572 steel grades. The objective was to improve toughness and reduce production variability through metallurgical and process optimizations.

| Condition | Depth within plate thickness | Temperature | Normalize Time (min/in) | Normalize Time (min) | Thickness (in) | Slab Grade | Charpy Avg |

|---|---|---|---|---|---|---|---|

| 1 | 1/4 T | 1650 | As Rolled | 0 | 0.875 | A516-70 | 44 |

| 2 | 1/4 T | 1650 | As Rolled | 0 | 0.75 | A516-70 | 39 |

| 3 | 1/4 T | 1650 | As Rolled | 0 | 0.75 | A516-70 | 42 |

| 4 | 1/2 T | 1650 | As Rolled | 0 | 1.375 | A516-70 | 22 |

| 5 | 1/2 T | 1650 | As Rolled | 0 | 1.375 | A516-70 | 9 |

| 6 | 1/2 T | 1650 | 30 | 45 | 1.375 | A516-70 | 20 |

| 7 | 1/4 T | 1650 | 30 | 45 | 1.375 | A516-70 | 13 |

| 8 | 1/4 T | 1650 | 30 | 40 | 1.29 | A516-70 | 37.67 |

| 9 | 1/2 T | 1650 | 30 | 40 | 1.29 | A516-70 | 31.33 |

| 10 | 1/4 T | 1650 | 60 | 80 | 1.31 | A516-70 | 30.67 |

| 11 | 1/2 T | 1650 | 60 | 80 | 1.31 | A516-70 | 20.67 |

| 12 | 1/4 T | 1650 | 30 | 25 | 0.79 | A516-70 | 47.33 |

| 13 | 1/4 T | 1650 | 60 | 50 | 0.78 | A516-70 | 44.67 |

| 14 | 1/4 T | 1650 | 30 | 20 | 0.65 | A516-70 | 43 |

| 15 | 1/4 T | 1650 | 60 | 40 | 0.67 | A516-70 | 41 |

| 16 | 1/4 T | 1650 | 30 | 25 | 0.78 | A516-70 | 54.67 |

| 17 | 1/4 T | 1650 | 60 | 50 | 0.8 | A516-70 | 51.67 |

| 18 | 1/4 T | 1700 | 30 | 30 | 1 | A516-70 | 24.33 |

| 19 | 1/4 T | 1700 | 60 | 60 | 1 | A516-70 | 42.67 |

| 20 | 1/4 T | 1700 | 30 | 35 | 1.15 | A516-70 | 37 |

| 21 | 1/4 T | 1700 | 60 | 70 | 1.15 | A516-70 | 33.67 |

Key Investigations:

- Microstructure & Chemistry Research: Examined microstructural features and chemical composition, focusing on elements such as Niobium, Vanadium, Molybdenum, and Silicon for grain refinement.

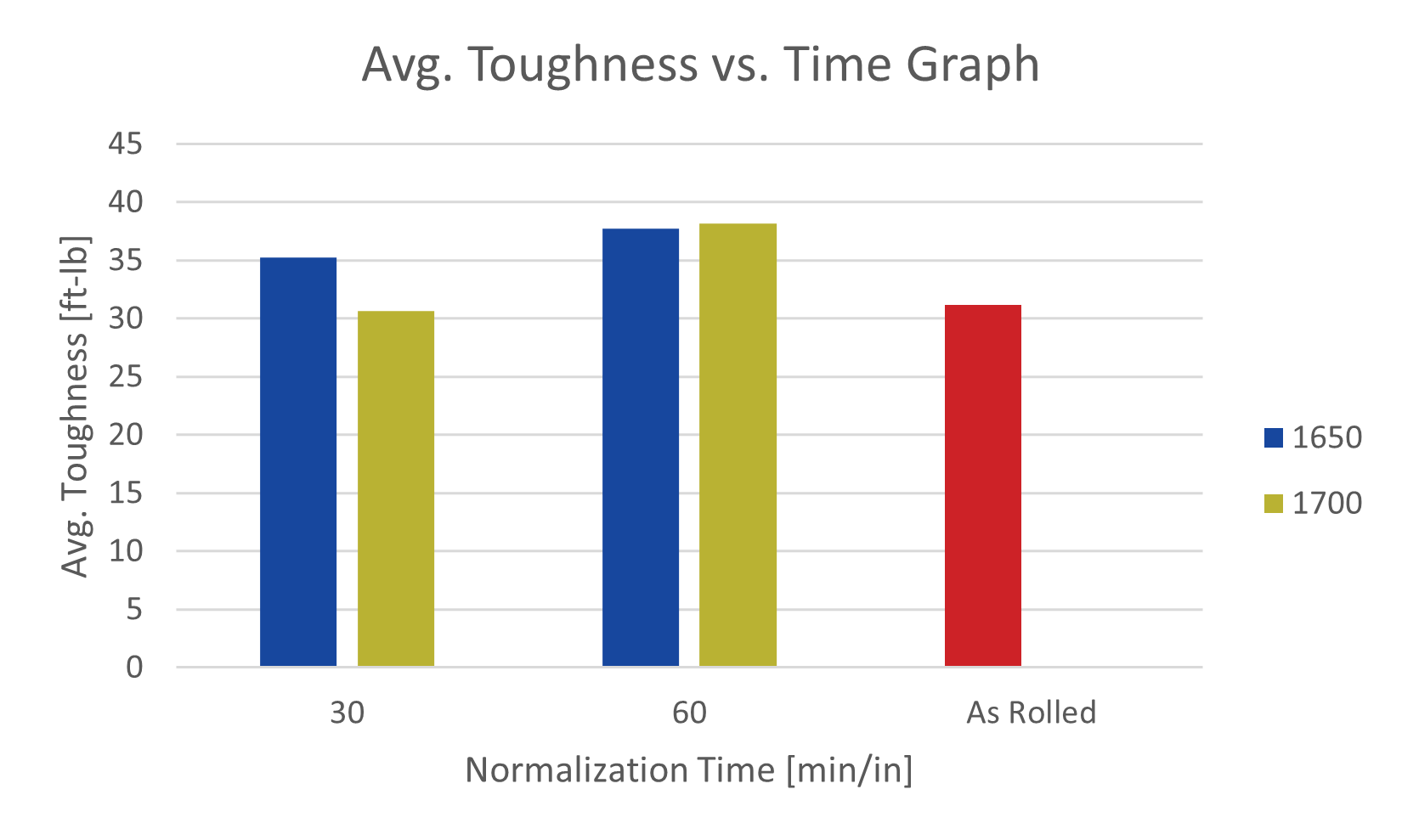

- Rolling & Heat Treatment Trials: Adjusted 4HI rolling parameters (entry/exit temperatures and drafts) and conducted normalizing trials at varying times and temperatures.

- Data Analysis: Used Minitab and Excel to correlate chemistry and process changes to Charpy impact toughness.

Results:

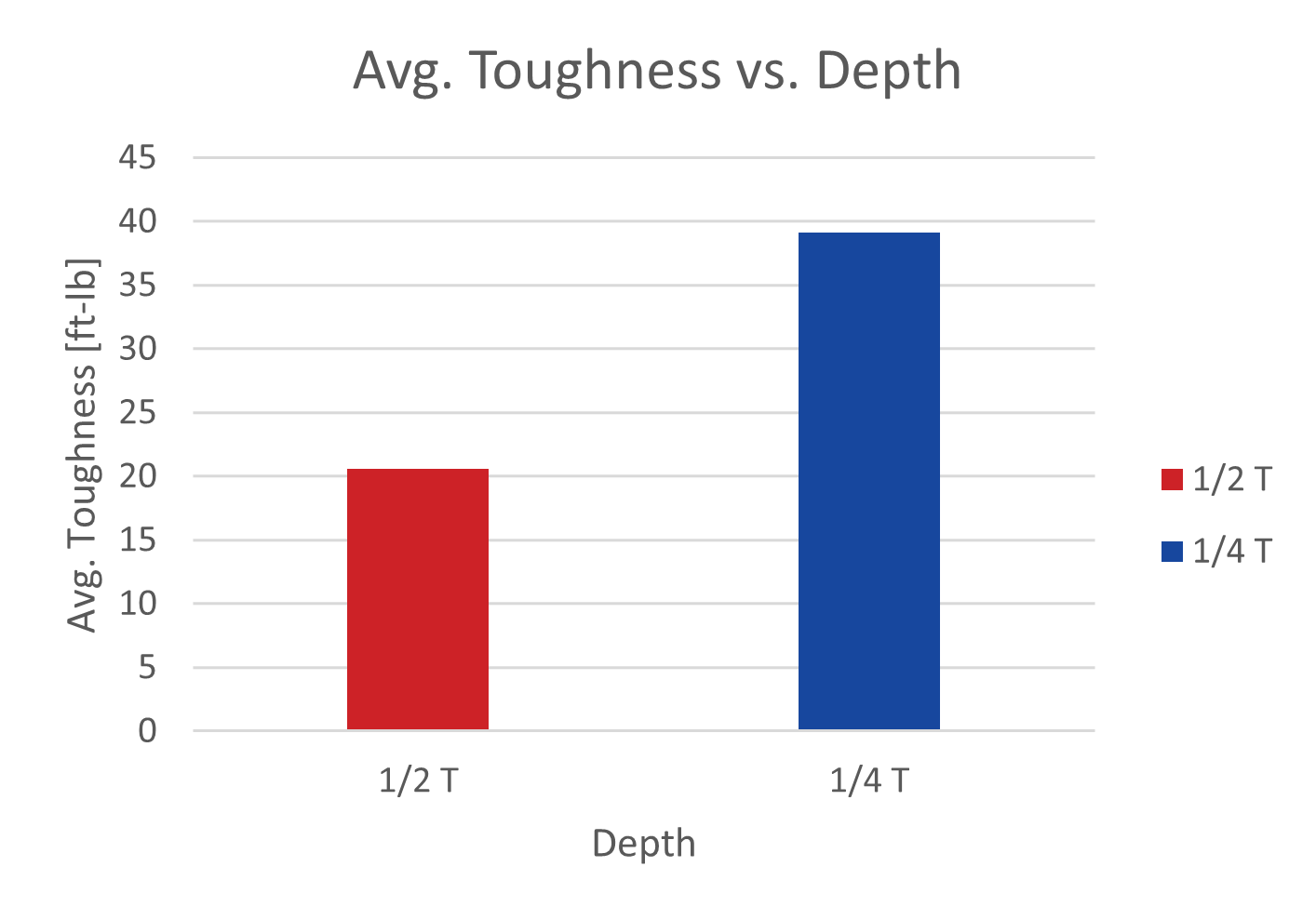

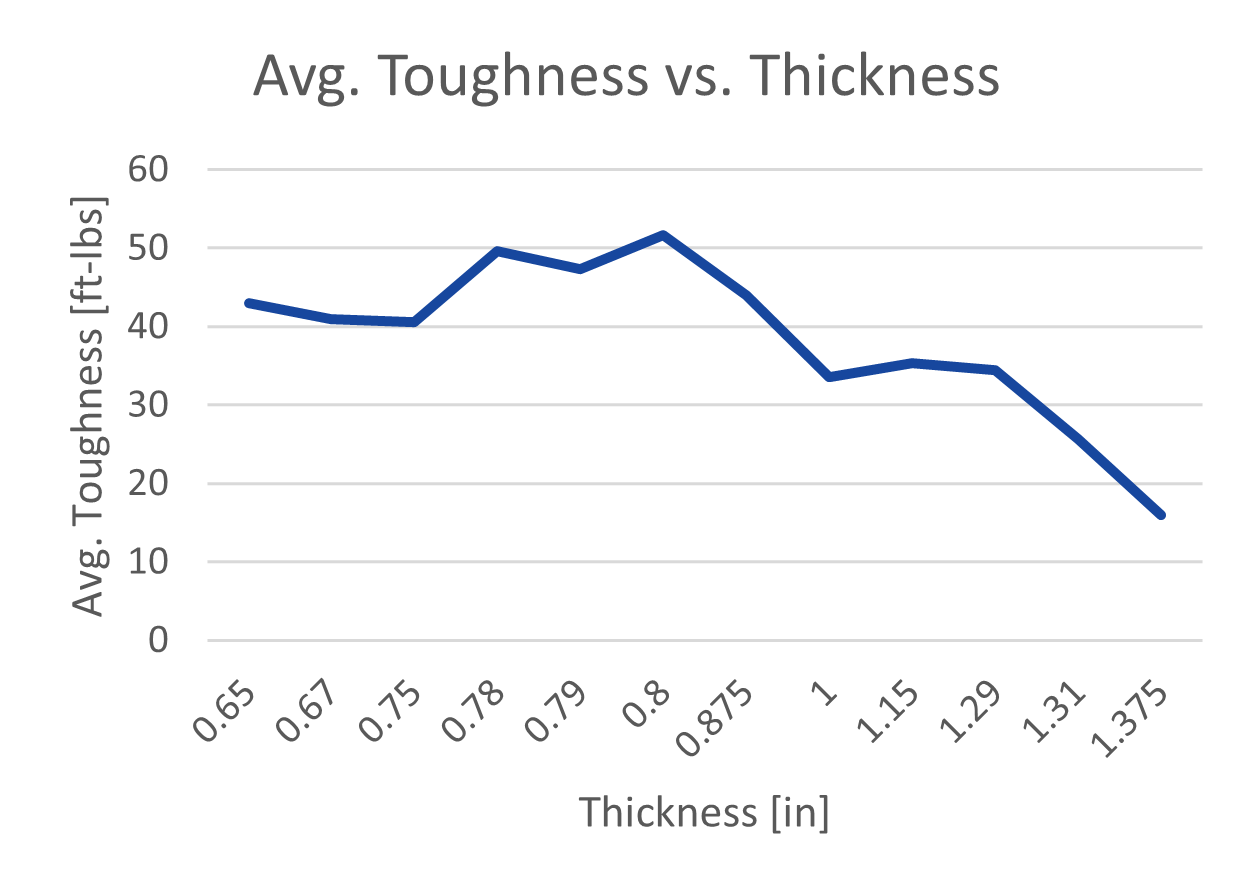

- ASTM A516-70: Increasing normalizing time or temperature did not significantly affect toughness. However, decreasing plate thickness led to better impact performance. New chemistry standards were proposed for Molybdenum (0.095–0.115%) and Silicon (0.3–0.4%).

- ASTM A572: Recommended reducing exit rolling temperature from 1400°F to 1300°F. Further validation is required for full implementation.

Tools & Skills Gained:

- Metallographic analysis, Charpy testing, regression modeling

- Root-cause analysis, collaborative trial planning, and technical presentations

This project strengthened my understanding of the interplay between composition, processing, and mechanical properties in industrial steelmaking.

Project information

- Category Technical

- Client JSW Steel USA

- Project date May 2024 - August 2024