Project Overview

This project was a comprehensive failure analysis investigation focused on premature corrosion observed beneath a household refrigerator ice dispenser. The study examined how design geometry, coating integrity, and service environment interact to produce localized corrosion in polymer-coated galvanized low-carbon steel.

The work was conducted with an industry-facing perspective, applying corrosion science principles commonly used in automotive and appliance design to a real-world consumer product failure. The goal was to identify the root cause of coating breakdown and rust formation and develop practical, design-driven recommendations to mitigate similar failures in future products.

The Challenge

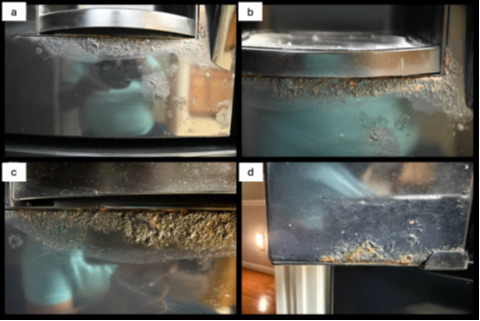

Despite the use of a polymer-coated galvanized steel panel intended to resist corrosion, localized rusting developed near the ice tray and dispenser region. This area is routinely exposed to:

- Repeated wetting and drying cycles

- Stagnant water accumulation

- Mineral-rich tap water

- Periodic cleaning with household chemicals

Over time, coating blistering and delamination were observed, eventually exposing the underlying steel substrate and accelerating corrosion. The failure raised questions about whether the issue was driven by material selection, coating performance, design geometry, or service conditions.

Investigation & Analysis

A structured failure analysis approach was used to build a complete understanding of the degradation mechanism:

- Macroscopic Inspection: Documented coating blistering, rust product formation, and correlation with moisture-retaining features near the dispenser seam.

- Material Identification: Handheld X-ray fluorescence (XRF) confirmed the panel material as galvanized low-carbon steel rather than stainless steel.

- Environmental Assessment: Water hardness measurements supported the presence of mineral residue and dissolved ions capable of promoting localized corrosion under thin electrolyte films.

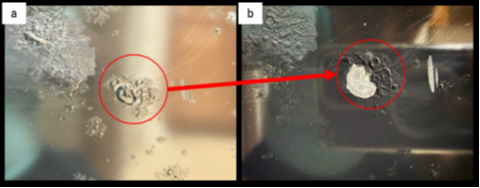

- Corrosion Mechanism Correlation: Damage matched under-film and chloride-assisted pitting corrosion behavior in galvanized steels.

- Thermal–Mechanical Simulation: A simplified model evaluated differential thermal expansion between polymer coating and steel substrate, supporting interface strain and adhesion loss near the seam during temperature cycling.

Failure Mechanism Identified

The dominant failure mode was under-film pitting corrosion initiated by coating delamination. Localized strain and moisture retention at the dispenser seam allowed water to penetrate beneath the polymer coating. Once trapped, the electrolyte dissolved the zinc coating, creating an aggressive microenvironment that consumed the sacrificial layer and exposed the steel substrate. The corrosion progressed largely unseen beneath the coating until blister rupture and visible rust formation occurred.

Proposed Solutions & Recommendations

Based on the analysis, the following engineering-driven recommendations were developed:

- Design Improvements: Introduce sloped surfaces or drainage paths near the dispenser region to eliminate stagnant water accumulation.

- Edge Sealing & Gasketing: Incorporate hydrophobic seals or capillary breaks at horizontal seams to prevent moisture ingress beneath the coating.

- Coating Controls: Improve surface pretreatment and ensure minimum coating thickness and coverage at edges and seams.

- User-Level Mitigation: Encourage periodic drying of the dispenser area to reduce long-term moisture exposure.

These recommendations directly target design-for-corrosion practices used in appliance and automotive industries to reduce warranty-driven failures.

Key Skills & Tools

- Failure Analysis & Root Cause Investigation

- Corrosion Mechanism Identification (Pitting & Under-Film Corrosion)

- Materials Identification via XRF

- Environmental & Service Condition Assessment

- Thermal–Mechanical Simulation (SolidWorks)

- Design-for-Reliability & Corrosion Engineering

Technical Report

Project information

- Category: Personal

- Project Date: August 2025 - December 2025